Woodturning Green Turned Vase From Backyard Red Bud

This post is best viewed here on this page. However, in case of technical difficulty, it is also posted on YouTube and FaceBook.

Several weeks ago, I turned a piece from an unknown tree harvested from my back yard. It has now been identified as red bug, a beautiful wood. After seeing how beautiful the wood turned out, I decided to turn a small vase from the same trunk.

Turned green, I then let it dry after coating with wood glue and wrapping in paper. When it stopped losing weight, I remounted the vase to finish it again.

Much of the hollowing was through the bottom which was later plugged. After all, why hollow through a tiny opening when I do not have to.

My vase is 5 by 3 inches finished with wipe-on poly.

Enjoy.

Woodturning Wide Sapele Platter / Bowl From Offcuts

Please view this post on this page. However, in case of video difficulty, it is also posted on YouTube and FaceBook.

I scored some sapele offcuts from an associate-not large enough individually. However, I could see a bowl or small platter – only larger. While I would prefer turning from a single piece of wood, I decided to glue three pieces together and go for it anyway. The wood is too beautiful to do otherwise.

Size: about 15 inches diameter by 2 inch, finished with wipe on poly.

Enjoy.

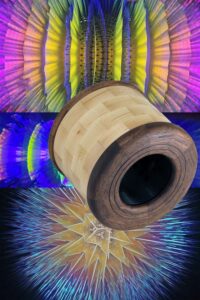

Cross Craft Segmented Woodturning Light Explodes Kaleidoscopes

Please view this post here on this page. However, if having technical difficulties, it is also posted on YouTube and FaceBook.

I find kaleidoscopes fascinating. Last fall, I participated in a workshop with Mark Tickle where I assembled a couple of his kaleidoscopes. Kaleidoscopes transmit light through an object cell containing random shapes and colors. Then light is reflected from a carefully arranged mirrors to produce a random, display of colors and patterns. Different mirror configurations produce different macro patterns while the random colored objects produce infinite detail.

Kaleidoscopes depend on light. As I created my kaleidoscopes, I thought of a supplemental light source that would make my kaleidoscopes pop even more. The design complements this style of kaleidoscopes.

I designed and 3d printed a core which holds a battery and positions LED’s. A segmented cylinder contains the core.

Items of interest:

- 6 segmented rings

- 12 segments per ring

- 72 total segments

- 2 2032 batteries

- 5 white LED’s

- Finish: Watco wipe on poly.

- Size: 4″ x 3.5″

- Kaleidoscope Design: Marc Tickle – www.OnReflection.com

Enjoy.

Woodturning Eccentric Tree – It Grew Up In The Wind

Please view this post here on this page. But if there are technical difficulties, it is also posted on YouTube and FaceBook.

Inspired by entries in last year’s Ornament Challenge. I am in an eccentric mood. Plus, we had a club demonstration wherein one of the projects was an evergreen tree.

I decided to take the demonstration tree to the level of the challenge tree. This requires a series of offsets to the turning axis to achieve a leaning tree or a tree that has grown up in a consistent prevailing wind, my mother’s “canyon breeze”.

The wood is aspen. This piece is solid, without checks common to aspen.

The tree is 6″ tall, 3″ diameter, finished with shellac.

Enjoy.

Woodturning Trembling Trembleur

In case of technical difficulties, this post is also posted on YouTube and FaceBook. However, it is best to stay right here!

I saw a couple of trembleurs in the instant gallery at the AAW symposium in Portland, Oregon. And, then, Eli Avisera did a demonstration that was very informative. The only significant difference between Eli’s process and mine is that I cheated and turned the trembleur from a round dowel instead of square stock. In my experience dowels have fairly straight grain which is perfect for a trembleur.

Size: about 12 inches long. Main shaft is about 1/8 inch. Started with 1/2 inch dowel.

A 3D model of a string steady cylinder is posted on Printables at:

https://www.printables.com/model/918546-lathetail-stock-string-steady-rest

My disk is mounted to an arbor from Little Machine Shop that I have had for some time. There are several MT2 arbors to choose from. If I were starting over, I’d look at this one.

Arbor, Drill Chuck 2MT Tang to 3/8″-24 Thread

https://littlemachineshop.com/products/product_view.php?ProductID=1613&category=

Waxed string is essential. Do not even think about having the disk rotate (it will flop).

Enjoy.

Woodturning Eccentric Single Piece Scoop

In case of video difficulties, this post is also posted on YouTube and FaceBook.

Inspired by a fantastic demonstration at the Portland American Woodturning Symposium by Eli Avisera.

This is an eccentric or multi-axis small scoop from a single piece of wood. It requires turning a sphere on the end of a spindle, then offsetting the axis to turn the main handle, then returning to the original axis to finish the handle. At long last, hollow the sphere to form the bowl of the scoop.

The octagon method for turning a sphere helped.

I also 3D printed a couple of accessories: a cup to receive the sphere while the handle was offset; and, a bushing or sleeve to hold the sphere while being hollowed.

3d Prints shared on www.Printables.com

Sleeve bushing – https://www.printables.com/model/904340-woodturning-bushing-to-make-scoops

Live Center cup faceplate – https://www.printables.com/model/904599-cup-center-for-live-center

Size: about 3.5″ x 1.5″. Finished with beeswax and mineral oil.

Enjoy.

Woodturning Mystery Bowl In A Board

This post is best viewed right here on this page. But, if you have difficulties, it is also posted on YouTube and FaceBook.

I wish I knew what species of this this bowl is turned from. It was a decorative tree in my back yard that I cut down. The wood is beautiful.

It is an interesting convergence of a square bowl and a bowl.

Size: about 7 x 2 and 2 High. Finished with walnut oil.

Enjoy.

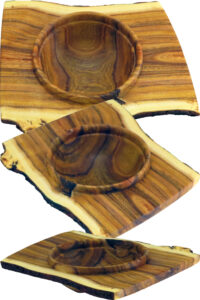

Woodturning Square Bowl From Venezuelan Saman

Just in case of technical difficulties, this post is also on YouTube and FaceBook.

I received this wood from a friend who had traveled and lived in Venezuela. He had returned with a “bookcase” of beautiful wood, saman. He was moving and need to find a new home for the wood. The wood was already 12″ square and 2″ thick. I trimmed it to remove dings in the edges.

Mounted with hot melt glue, I turned a mortise. But at the last minute, the hot melt glue failed. Why? too heavy, too little glue, operator error? I had other difficulties but continued until I now have a square bowl, almost a platter.

It is still almost 12″ square, finished with wipe-on poly.

Beautiful wood.

Enjoy.

Cottonwood Burl Bowl – Required Three First Aid Treatments

Please view this post here on this page. But if there are technical difficulties, it is also available on YouTube and FaceBook.

Salvaged from a friend’s burn pile, this cottonwood burl took some TLC and a redesign but not that much TLC. It is well worth the UV resin and CA needed to bring out its beauty.

Size: about 11 diameter and 3 tall. Finished with wipe-on poly.

UV resin: Amazon SANAAA UV Resin Clear Hard Type 500g Transparent UV Solar Curing Resin

CA glue: Almost anywhere

Enjoy.

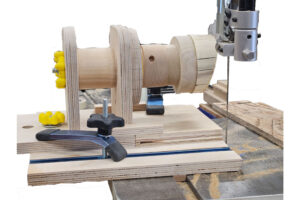

Woodturner’s Band Saw Sled – Essential for Advanced Projects

In the remote possibility of technical difficulties, this post is also available at YouTube and FaceBook.

Best Right Here!

While making last week’s project, it was an appropriate time to upgrade my band saw sled incorporating inspiration from a demonstration at last year’s Rocky Mountain Symposium in Colorado.

In that demonstration, he used a sled that had some features that I thought would be good to incorporate into the sled I have been using and upgrading for several years. One problem – these features depended on a salvaged lathe spindle. The spindle provided a threaded mount and length for stability. My previous sled used a 3D printed knob that held a chuck or threaed faceplate to a 3/4″ plywood.

Then the idea hit. I had also designed and 3D printed a chuck hub that could serve a similar purpose. And, in fact, would be even better and much less expensive.

My new design will cut arc’, sloped cuts, straight cuts, and freehand cuts. For each cut the turning project is mounted to a chuck or threaded faceplate. Then, with the sled, it can be safely cut. This design also enables exact offset cuts by using a spacer inserted behind the plywood base holding the chuck hub. Therefore, all other settings are preserved – no dismantling required for the offset.

Projects that follow John Beaver require offset curve cuts. My Celtic knot vases require offset slant cuts at specific rotations.

Dimensions depend on the bandsaw capacity. I share my dimensions and their rationale in the video. Please adapt to your equipment. Please also share your enhancements.

Chuck hubs and knobs that match popular spindle sizes are available at by Etsy store at

https://www.etsy.com/shop/AsWoodTurnsTools

Universal T-Track hardware, I purchased from HomeDepot.com.

Enjoy.

p.s. If you would like a more in depth demonstration than my weekly videos, please contact me for an IRD (Zoom Demo) on this or other topics.