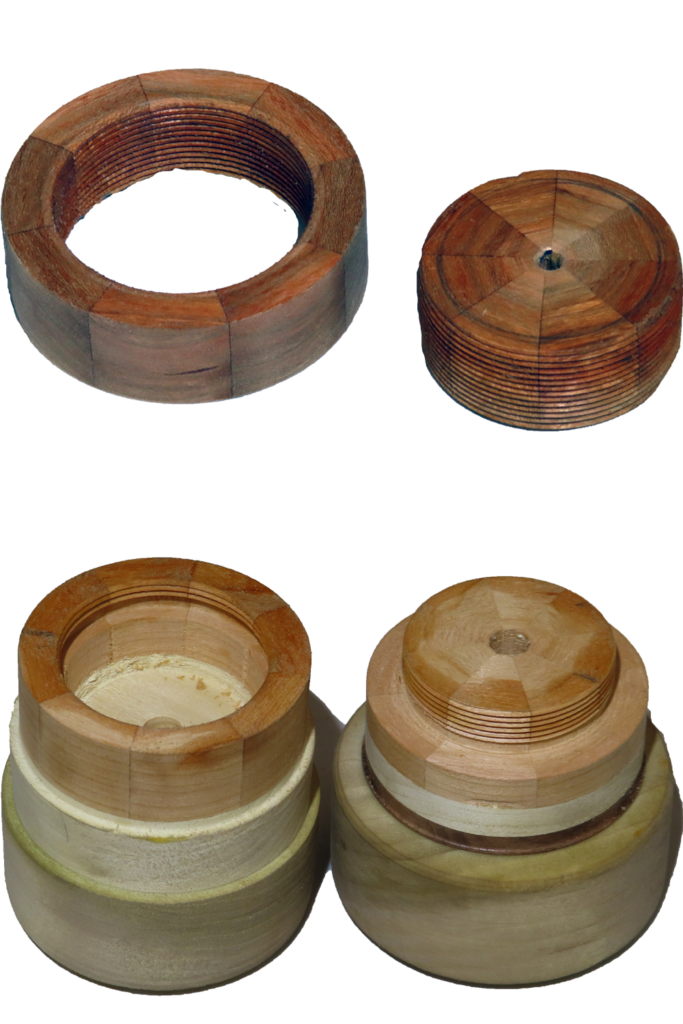

Woodturning Hand Chase Threads – Three Plus Critical Tips

In case of difficulty viewing this post, it is also posted on YouTube (link) and FaceBook(Link).

Threading can be intimidating. Expensive wood, fine detail, high risk for destroying a project.

What to do?

- Separate threading from the main project. Thread an insert. While inserts can be purchased, with a little practice, you can make your own.

- Use common woods such as cherry, poplar, maple in a segmented disk for your insert. These are sustainable woods that do not deplete the rain forest.

- Overcome fear of threading: In this video, we address how to train yourself to the appropriate rhythm for threading and how to avoid double threading.

BTW, for a 16 tpi, the distance from the peak of a thread to its valley is about .08 of an inch. For 10 tpi – ~ .13; for 20 tpi .065.

Threading tools come mainly in 10, 16, and 20 threads per inch (tpi) and are available at Craft Supplies USA, Amazon and others.

I lubricated the threads with walnut oil.

Enjoy!

Woodturning Oak & Plum Burl Cross Grain Box

In case of viewing difficulty, this video is also posted on YouTube and FaceBook.

I turned the project in preparation for a club remote demonstration. The base is nicely figured white oak. The lid is plum with a lot of burl figure.

A cross-grain box like this one requires at least six mounts or remounts: three for each piece. The first is for the rough one; each then requires a top and bottom mounting. Some are in compression mode while others is expanding into mortises both deep and shallow.

I used a pin faceplate for the first mount of each piece. It was pretty handy. I prefer it to using the face of closed chuck jaws.

I think it turned out nice.

Enjoy!

P.S. You can see my list of club demonstration topics at www.AsWoodTurns.com/Demonstrations/

Woodturning Double Triple Celtic Knot

In case of difficulty, this video is also posted on YouTube and FaceBook.

This project features a walnut vase with two sets of Celtic knot loops of maple. It is 2.5 inches diameter and six inches tall.

Helpful equipment and accessories are:

- 2 hexagon templates sized for the maximum capacity of my tablesaw. These are drawn in software and printed then glued to .25 inch plywood or hardboard. I saw and sand to the line.

- a tablesaw sled to which I can temporarily fasten scrap to position my project for sawing.

- hot melt glue gun.

I screw the templates to the rough turned stock at the center and hot melt for additional security.

After positioning the project with templates on the sled at an angle of choice, I fastened scrap pieces to the tablesaw sled to enable returning the project to the same position on the sled.

Before sawing, I also fasten scrap to the top of the project with hot melt glue. This wood maintains the relative position of the two halves of the project that soon will be.

Then saw but not through the positioning scrap.

Now glue in the replacement wood. I used maple.

Repeat for each loop. However, I changed the angle after sawing every other point on my hexagon before sawing the next three alternating loops.

Then hollow and shape to taste.

Enjoy!

Woodturning Spiral Segmented Vase With Blooper Fix

In case of difficulty, this video is also posted on YouTube and FaceBook.

With this project, I am exploring more into segmented turning. Beyond plain rings, this vase features a spiral at 120 degrees apart around the vase.

Featuring 15 rings of 12 segments each, the segment count is 180 segments plus the base which is 3 plys of maple. The vase is finished with walnut oil for a nice matte finish. It stands about 8 inches tall and 7 inches in diameter.

I made a mistake in the second layer. My segments were not correctly spaced. I did not notice the error until the bottom section had been glued up. I had to remove the bad ring and replace it. But noone would be able to tell the difference.

For the steady rest, please see my video where I review it.

Woodturning – My DIY Steady Rest Is Still Steady

Enjoy!

Woodturning Mesquite Vase – Rough and Tough From Green To Finished

In case of viewing difficulty, this video is also posted on YouTube and FaceBook.

I picked up this mesquite in Arizona over a year ago. Shortly after bringing it home, I rough turned and partially hollowed it. I only partially hollowed it because I was still working on my hollowing rig at the time. I regret not hollowing it more while green and a little softer.

I sealed the wet wood with Bowl Save from Craft Supplies USA, a PVA based wood sealer and let it dry.

Once dry and harder, I finished hollowing and then finished the outside. It is difficult to show hollowing since the real action is inside the vase – out of sight. I use a USB borescope camera on the hollowing rig. The camera moves with the cutting bit. Even though the bit is inside the vase, it still shows the relative position of the cutter and the outer wall of the vase on the screen.

For those wondering why the hollowing video segment is so poor. The tool is marked on an transparency covering the screen. What you can see is a camera shot of my small screen including the transparency. For you tech savvy people, I challenge you to find a better way to show this setup.

The vase is five inches diameter and six inches tall finished with walnut oil.

For the steady rest, please see my video where I review it.

Woodturning – My DIY Steady Rest Is Still Steady

Enjoy!

Woodturning Segmented Platter – Tips, Tricks, and Bloopers

In case of viewing difficulty, this video is also posted to YouTube and FaceBook. Best to stay right here!

For this project, I am pushing my limits. After my move from Oregon to Utah, I had several project crack from the change in humidity. These were generally flatter projects with long butt joints. I resolved to turn a platter that would not crack.

One issue is the outer rim when segments extend out often with limited support and on this platter – no support. The butt joints between segments are very sensitive to changes in humidity and risk cracks. To resolve this, the outer ring is a lamentation of two rings with the joints offset. This plan supports the butt joints with stronger side grain joints.

In addition, since the project is flat, rings cannot bricklay on top of each other. Instead, I cut matching bevels on each pair of rings. The bevel gives a lot of forgiveness in matching the joints and extends the glue line a little bit.

The platter contains 48 segments in walnut and hickory. In addition, the center is 3 plys of maple cross-banded to constrain grain movement. The platter is about 10 inches in diameter and finished with walnut oil.

Enjoy!

Woodturning Olive Vase – Green to Dry to Finished

In case of difficulty, this video is also available on YouTube and FaceBook.

The last time I visited Arizona, I brought back some trunks of olive and mesquite. This piece was a smaller section from an olive tree. Most of the piece was sapwood without the usual dramatic heartwood figure. Observing this and talking it over with the wood, we decided to turn a vase. The wood was still wet so we had to rough turn it and let it dry. While rough turning, a drill took care of the pith – the root of all evil cracks.

A year later, we decided it was dry enough to finish turning. It is finished with shellac friction polish and buffed to a nice sheen.

The vase is 3 inches in diameter and seven inches tall.

Enjoy!

Segmented Woodturning – Experimenting With Splines

In case of difficulty, this video is also posted on YouTube(link) and FaceBook (link). Best right here already!

I have had a hair-brain idea for a while now to use splines to enhance a segmented woodturning, particularly a bowl. There are times to use a spline to fix a project. In addition, this is a time to use a spline to decorate or elevate a project to a new level.

This project uses 12 segments per ring in 7 segmented rings plus 6 splines. The main body is cherry, the top ring and splines are walnut. The finish is walnut oil then buffed to a nice shine. Size is 8 inches diameter and 6 inches tall.

The experiment in this project is to insert splines in the segment rings. I had not seen this done previously. The trick was now to make the cuts safely on my table saw. The solution turned out to be a simple tall fence screwed to the saw’s miter gauge. To prevent the wood from shifting, I did not cut completely through the segment ring. This was also the case when I did Celtic knots.

I tried to be conservative this time with the spline since this was a first experiment. With this background, future projects will have more exotic placements.

Enjoy!

Woodturning Hollow Form Vase – Green to Rough to Finished

In case of difficulty, this video is also posted on YouTube(link) and FaceBook(link).

I started turning this vase shortly after receiving it in a club wood raffle. It was still wet. It seemed to be perfect for a hollow form turning. I rough turned the outside and hollowed it while still green.

After coating it with a PVA based wood sealer from Craft Supplies USA, I let it dry for about 18 months. I weighed it periodically to assess how much moisture had been lost.

Remounting a dry but warped project is always part of the challenge. In this case I had placed a scrap disk over the entry to the inside to limit air movement. This now served as a tenon while I recut a tenon on the base.

Then on to cut off the sealer and trim the hollow form to final shape. I wanted a smooth curve.

In this case I used a sanding pad to remove the last of the nub on the bottom. I put the sanding pad in a #2 Morse taper collet sized to the pad’s shaft. Then a drawbar holds the collet securely to the spindle. This works better than a Jacobs chuck in the spindle.

This vase is finished with walnut oil.It measures about 6 inches in diameter and 5 inches tall.

Enjoy!

Woodturning Segmented Lidded Vase With Invisible Connection

In case of difficulty, this is also posted on YouTube(link) and FaceBook(link).

For this vase, I wanted to have a lid. Not just a lid but one that had an invisible connection. My segmented vase was a perfect opportunity. If I prepared the vase right, I could hide magnets in a segmented ring. Besides being invisible, their power would also be invisible.

So, I embedded eight 6mm x 3mm ferrite magnets in the joint. A layer of segmented wood hids the magnets. While the wood reduces the power of the magnets, they are still strong enough that I can hold this vase upside down.

This vase is 4″ diameter and 6″ tall finished with walnut oil.

I used quite a few threaded wood faceplates as I needed to hold segmented rings from both side at times. My Live Tailstock Chuck Adapter from Penn State also came in very handy in aligning segmented rings to a faceplate and when parting a ring into two smaller rings.

Enjoy!