by

Alan Stratton on Friday, June 28th, 2013 |

4 Comments

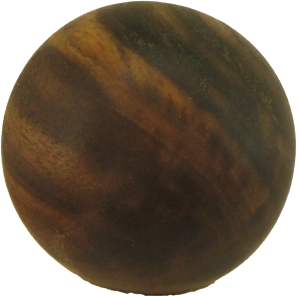

| One project during a week long woodturning class a few years ago was a wood ball using a jamb chuck. I failed miserably to get the ball smooth. It ended up very rough and out of round. With this failure, I feared being able to make a good ball.

Since then, I’ve looked for a jig or a process to turn a perfect ball or sphere. I doubted I could do it myself. I looked at commercial jigs – expensive and plans for DIY jigs – difficult to make and potentially inaccurate.

More recently, I watch Dale Larson and Alan Lacer both turn perfect balls using only simple faceplates. Now I can do this.

Here’s the process I used:

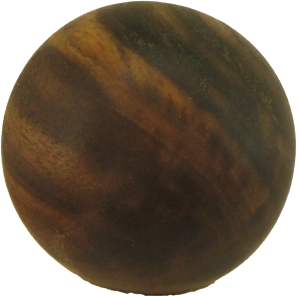

- Make two faceplates with small cup centers. I’ll make another video to describe these.

- Turn a cylinder between centers a little longer than the target diameter of the ball.

- Measure the cylinder diameter and transfer this to the side of the cylinder.

- Mark the mid line of the cylinder.

- Part down outside the end lines leaving only a small tenon on each side of the ball.

- Round over the cylinder corners into an approximate ball shape.

- Saw off the two end tenons.

- Mount the two faceplates to the headstock and tailstock

- Mount the ball between the two faceplates with the axis rotated 90 degrees. The mid line now runs across the ball from one faceplate to the other.

- Carefully cut and/or scrape the ball to eliminate the ghost image on the back side of the ball as it rotates, making sure to leave the pencil line running from side to side.

- Draw a new mid line.

- Rotate the ball so that the new mid line runs from faceplate to faceplate.

- Repeat step 10.

- If I’ve cut too deeply, repeat steps 10 thru 12 until the ball is perfectly round.

- Sand repeating steps 10 thru 12 using sandpaper instead of a cutting tool for each grit

- Apply finish (I used beeswax and mineral oil) repeating steps 10 thru 12 using finish.

After a couple of balls, I could make another ball in very little time.

Success – my ball turning phobia is gone.

My next video will describe the faceplates for turning wood balls.

Another video will take the process to a new extreme. |

|

Tags:

Alan Stratton,

ball,

DIY woodworking,

Do It Yourself (Hobby),

Hobby (Website Category),

how to,

jig,

lathe,

powermatic 3520,

safety,

wood ball,

wood project,

Wood projects,

wood turning,

wooden balls,

woodturning,

woodturning projects,

woodturning tool,

woodworking projects Posted in

Tools and Jigs

Alan Hi!

Do you use beeswax and mineral oil separately or is it a speciel mix you purchasing or making yourself?

You are good Alan! It’s great to just watch and see how you do.

Best regards from Hanne

It’s a mix. In fact I just made another batch.

4oz beeswax + 1 pint of mineral oil about a 25%-75% mix.

Heat together in a double boiler until wax melts and stir together.

Let cool but while still liquid, pour into a container.

Use from the container for sanding and/or finishing or in the faceplate case – lubrication.

Both components are safe to eat.

I use it on many projects.

Alan Stratton

Hi there!

I was just wondering what it would take to get 3 spherical balls turned and then cut in half from you. Or Perhaps 6 sperical domes. They are for an accent on a cradle I made.

DeAnna Drake

I hesitate the quote without knowing size, species, and other details. Even then special orders are expensive.

If you have access to a lathe, watch the video and make them yourself. It will complement the work you’ve already done.

If you don’t, then get acquainted with a local woodturner who can do you a favor. Show them my videos and they’ll be off and running.

Alan Stratton